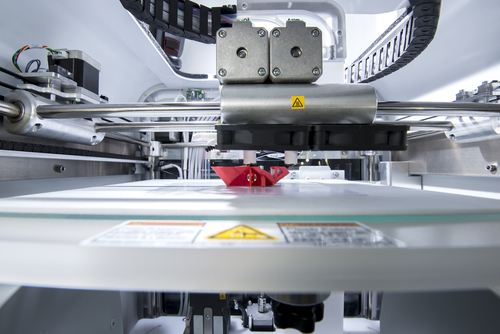

The 3D printing process is used to create an object from a three-dimensional digital model. The model of an object to be created is usually designed in a computer program, specially meant for this purpose. The objects are made by joining the materials layer by layer in conformity to the model. Since it adds up to an object, it is also known as additive manufacturing.

The 3D printing process is used to create an object from a three-dimensional digital model. The model of an object to be created is usually designed in a computer program, specially meant for this purpose. The objects are made by joining the materials layer by layer in conformity to the model. Since it adds up to an object, it is also known as additive manufacturing.

The technology began a few decades before under the term ‘rapid prototyping’ since its purpose was to prototype products quickly and cost-effectively. A lot has changed since its early days, and now 3D printing offers amazing outputs and helps in the creation of just about anything imaginable.

3D printing is an ideal manufacturing approach for producing items out of metal, plastic, ceramic as well as other materials. The process allows for rapid production of both prototypes and finished products. Additive manufacturing also creates components with intricate shapes that cannot be made by conventional methods that work the opposite way to it. One such ‘subtractive’ process is machining, which carves out objects from solid blocks leaving some amount of scrap.

Additive manufacturing is not likely to replace traditional methods at an industrial level, but the former can also be used to complement the latter. When used in combination with a tool and die machining, injection molding, and other methods, it enhances the quality of the product and extends the range of what can be made.

Key Benefits of 3D Printing

One of the main benefits of 3D printing is the pace at which components can be made as opposed to traditional processes. Intricate designs of products can be uploaded from the respective CAD model and be printed in a matter of hours. The benefit of this is the quick verification as well as the development of the design ideas. The more industrial 3D printing processes take relatively longer to both print as well as post-process components, though it has the capability to make end parts at either low or medium volumes. This saves significant time; in comparison, the lead time upon an injection molding die often is usually more.

3D printing is a capital-intensive process rather than labor-intensive. This means that most of the costs are related to material and machine operation. Industrial 3D printing technologies use a significant amount of energy to manufacture a single component. However, the capability to make complex geometries at one-go leads to superior efficiency and turnaround. The material cost contributes to a component’s cost the most. The labor cost is very low in AM. Post-process aside, most 3D printers only necessitate a limited number of operators. At the press of a button, the printer follows a fully automated process to manufacture a component.

The limits imposed by conventional manufacturing upon what can be produced are usually irrelevant for the additive manufacturing process. Since parts are constructed a layer at a time, the design requirements like draft angles undercut as well as tool access, do not apply when designing components to be “3D printed”.

Ideal For Manufacturing

While some restrictions are there on minimum size elements that can be correctly printed, most limitations of 3D printing revolve around how to orientate a print optimally so as to reduce the  support dependency as well as the possibility of print failure. This provides more design freedom and makes the creation of extremely complex geometries possible relatively easily.

support dependency as well as the possibility of print failure. This provides more design freedom and makes the creation of extremely complex geometries possible relatively easily.

3D printing allows not just more design freedom, but also full personalization of designs. As present 3D printing technologies excel in creating one part at a time, they are ideally suited for one-off manufacturing.

This also means additive manufacturing usually consumes only the required material to build a component. Most methods use recyclable and reusable raw materials in more than a single build. Therefore, the process generates very little scrap or waste.

The manufacturing process is common in several sectors. The most common industries served by it are as follows.

- Transportation: Components for automobiles, railcars, and aircraft.

- Consumer Goods: Extremely stylized jewelry, personal hygiene items, etc.

- Electronics: Ultra-precise metal and plastic parts for communications, computing, and more.

- Medical: 3D printing excels at making the design elements that are used in medical devices, like internal chambers, curves, and channels.

- Manufacturing: Replacement components for industrial equipment units to extend their life, and to minimize the downtime as well as costs associated with any unplanned maintenance.

As of late, a rocket having 3D printed components was successfully sent to space by the US. By reworking its ducting system with 3D printed parts, the assembly was reduced to just sixteen components, which provided cost savings of up to 57%.

The engineers at Pacific Die Casting orient components to offer the best possible quality production in the shortest possible time span. No matter what your budget or scheduling constraints are, contact us and we will see what can be done for you.

If you feel you need a physical 3D prototype before beginning the mold fabrication, Pacific Die Casting’s new Rapid Prototyping System can quickly turn computer design data into a 3D prototype.

Here is how it can help:

- 3D physical prototype in 24 hours

- Communicate and evaluate design concepts more efficiently

- Collaborate with partners and vendors more effectively

- Rapid SLA prototyping machines

- 3D prototype of automotive parts

- SLA models with finished die casting parts